Action truing is the process in which factory actions are re-worked to make them more precise. The fit, alignment, and tolerances of the receiver and bolt are greatly improved and with a full complement of modifications, most factory actions can be made to shoot as accurately as any custom action. It should be noted however, that action truing is usually only done when fitting a new barrel. This is because all of the critical areas in the receiver and bolt are re-machined as part of the truing process and because of this, the original factory barrel will no longer fit.

Some factory barrels have enough meat in the knox form (section of barrel directly in front of the receiver) to set the barrel back, cut and thread a new tennon and re-chamber, but often they do not.

I offer this service in two levels, Basic and full..

The Basic action true includes re-cutting the receiver face, internal lug faces, and ring threads true with single point tools. The receiver is mounted in a special jig in the lathe and a precision test bar is mounted in its bore on specially made precision fit bushes. This whole assembly is then dialed to run true with the lathe axis. Once it's running true the test bar and bushes are removed and the critical surfaces are then re-machined..

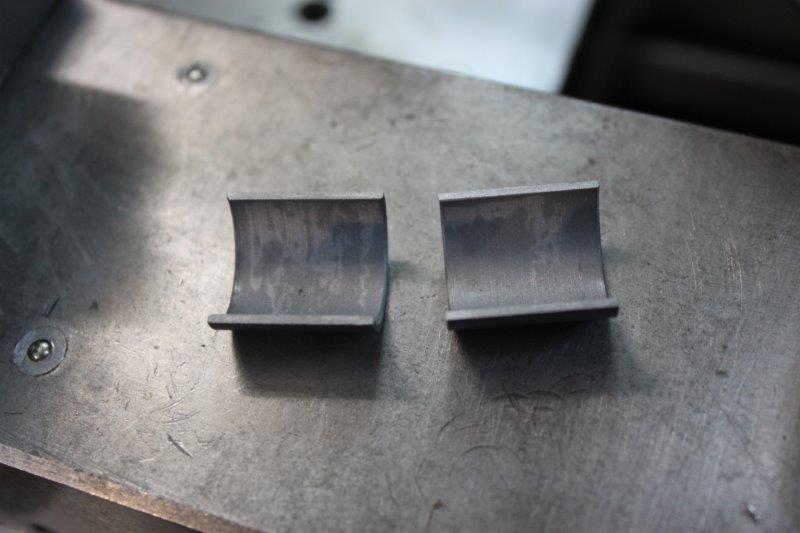

The bolt is also setup in a special jig between centers on the lathe. Once again the whole assembly is set to run true to the lathe axis and the lug faces, bolt nose, and bolt face are re-cut.

The full true includes everything from the basic true, plus the rear of the bolt body is bushed and machined to be a more precise fit in the receiver, and the firing pin hole is bushed and re-drilled to closely match the firing pin. ( Or drilled to 0.062" and the firing pin turned down to suit.)