The barrel is of course the heart of any rifle. It doesn't matter how good all the other elements of the rifle system are, if the barrel and chamber isn't up to scratch then it just won't shoot well..

There are a number of different methods used by smiths these days to fit barrels. Barrel fitting methods have come a long way in the last 20 years and the days of just setting up the barrels between centers for turning and then setting and chambering on the steady rest are long gone.

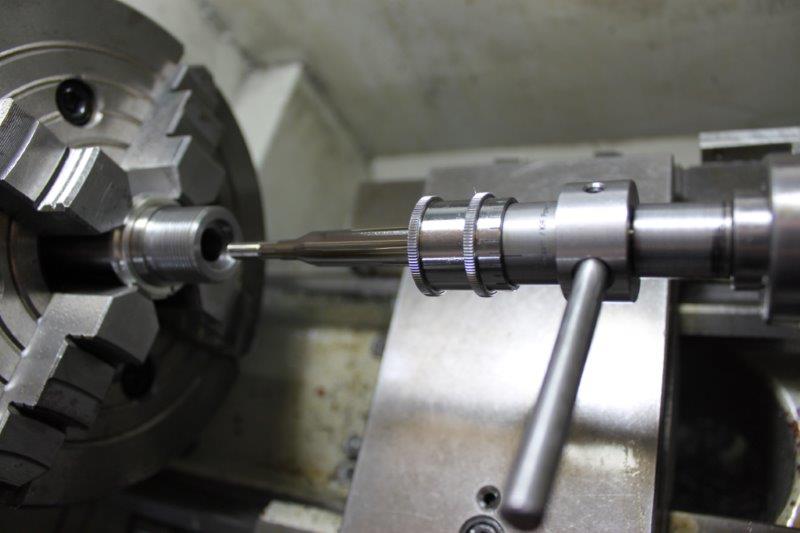

Most accuracy smiths are now working with the barrel set up through the headstock and this is the way that I do it. I use specially made aluminum collars to hold the barrel in a 4 jaw chuck while the outboard end is supported by another aluminum collar held in a specially made spider chuck. This way the barrel bore can be dialed in to run exactly true with the lathe center line.

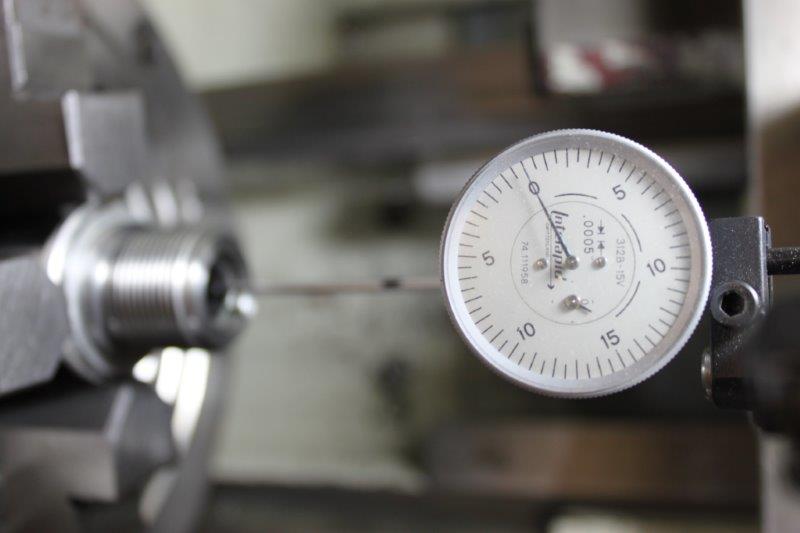

To dial barrels in true to the axis of the lathe I use high quality Interapid and Mitutoyo 0.0005” lever type dial test indicators with a 2.5” and 3.0" long stylus. This allows me to reach right up inside the bore and directly indicate the lands and grooves of the barrel. This method has several advantages over other indirect methods such as using piloted taper gauge pins etc.

Firstly it is a direct contact reading. The trueness achieved with Piloted taper gauge pins (or similar inserted up into the barrel) rely on the precision and straightness of the gauge pin its self, the precision of the pilot, and then it’s fit on the pin and in the bore. Even small errors in all of the above tend to accumulate and are then greatly magnified buy the length of the gauge pin.

Using a long probe indicator removes all of those potential errors because it’s directly in contact with the surface of the bore. Secondly using a probe also allows me to indicate both the tops of the lands and bottom of the grooves. The consistency of the land and groove depth is a great indicator of the quality of the barrel being used. All the lands should be a consistent height and grooves a consistent depth. Barrels are dialed in as close as I can achieve with that particular barrel. Every barrel is different but really good quality barrels can be dialed in to within 0.0002” or 0.005mm.

Once dialed true the barrel tennon is turned with high quality Carbide insert tooling and threading is done with “full form” carbide threading inserts. The use of full form inserts ensure that threads are always the same correct form every time. Chambers are then pre drilled to remove most of the material and then taper bored true again with a carbide micro boring bar. This normally leaves about 0.020” or 0.5mm of material for the reamer to remove.

I only use live piloted reamers from Pacific Tool and Gauge in the USA. Using a correct fitting live pilot is absolutely vital in achieving a precisely centered and sized chamber. I will not use solid pilot reamers, ever! Reamers are pushed with a shop made floating reamer holder to ensure a correctly sized chamber. Once finished, reamed chambers are polished to give a smooth uniform finish and then inspected for trueness with the dial indicator and the surface finish visually checked with a quality hawk eye borescope.

I will fit and chamber all barrel makes and sizes from 18” length and up, and up to 2” dia.

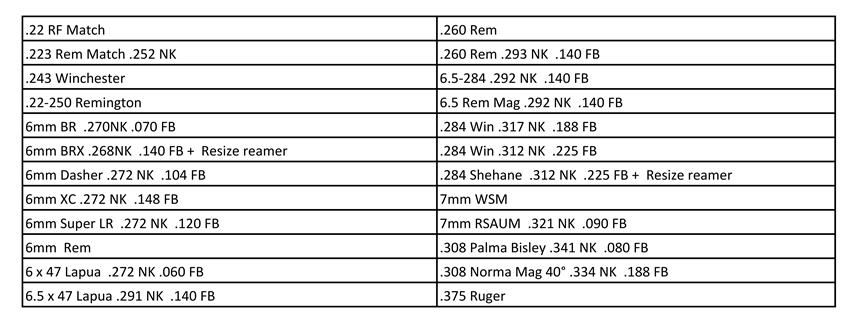

See Below for my current reamer list. I am expanding the list all the time so if you can't find the chambering your looking for, by all means contact me and we can order a reamer in for you.

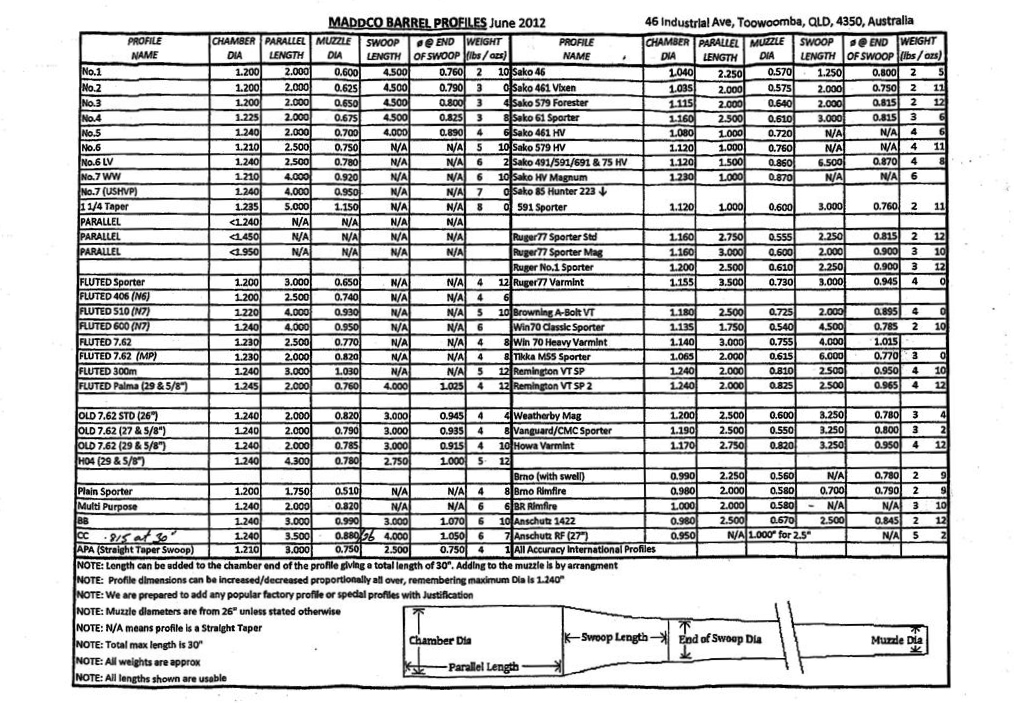

I use and highly recommend Maddco barrels..

Barrel fitting FAQ

Q: Do you give an accuracy guarantee when fitting barrrels?

A: No. Numerous factors and combinations determine finial accuracy in any rifle system and so no barrel maker will offer a guarantee of accuracy at the target for their barrels. Given the above i therefore cannot offer an accuracy guarantee to you either. However what i can guarantee is fitting and chamber work to the highest precision tolerances achievable and absolute minimum run out of chamber to barrel bore. I guarantee less than 0.0002" of run out in the chamber of a quality match barrel.

Q: I've had a look at your reamer list and i don't see the cartridge i want listed. Can you order in a reamer?

A: Yes. In some cases i will be more than happy to order in a reamer at no cost to you if i think it will be popular and i can get reasonable use from it. If it's to be an obscure cartridge or one with little following then i would need to add the cost of the reamer to your job. This would also be the case if you request a custom reamer to your specs. In any case where the customer has borne the full cost of the reamer it would be theirs to keep at the end of the job. In some cases a compromise may be reached where we can split the cost of the reamer.

Q: I have a factory chambered barrel, can you fit it to my action?

A: It depends.. For the most part i don't like working with poor quality factory barrels. Often factory chambers and bores are very loose and these are hard to clean up with my minimum spec chamber reamers. Some factory barrel steels are also very difficult to machine and are very hard on reamers. Typically hammer forged barrels like those found on Sako and Tikka rifles are about the worst and as such i will not re-chamber any hammer forged barrel. It should also be noted that given the wide variation of factory barrel dimensions and tolerances, absolutely no guarantee of accuracy will be given when working with a factory barrel.

Q: Your reamer has a tight turned neck, can you make it into a no turn neck?

A: Yes. For some calibers i have factory size neck reamer which is used to open out the neck dia. These are listed in my reamer list..

Q: I want to run a particular weight of projectile, can you throat the chamber to suit?

A: Yes, but it depends on the parent reamer. I try to list the "freebore" on all of my custom reamers. I can throat chambers longer than the reamer spec but obviously i can't make them shorter. I have throating reamers in all of the common calibers, all of which are listed in my reamer list. If throating is to be done then i will request some sample dummy rounds with the chosen projectile seated at the desired length. I can then throat the chamber to suit these.

Q: My barrel blank is fluted, can you index the flutes to line up with the action?

A: Yes, however it may be a compromise on precision. No barrel is ever perfectly straight. I deal with the run out by indexing every barrel so that the high point of run out is aligned with the top of the receiver. This results in a slight gain in elevation which is beneficial in most rifles. If i index the barrel to the flutes then unless the high point of run out lines up perfectly with a flute (rarely) then there will be some deviation to the left or right. The amount of deviation can vary with every barrel and so i have to decide at the time of fitting if indexing to a flute is going to be an issue.